Project details

- Type of Works: Pressure Vessels

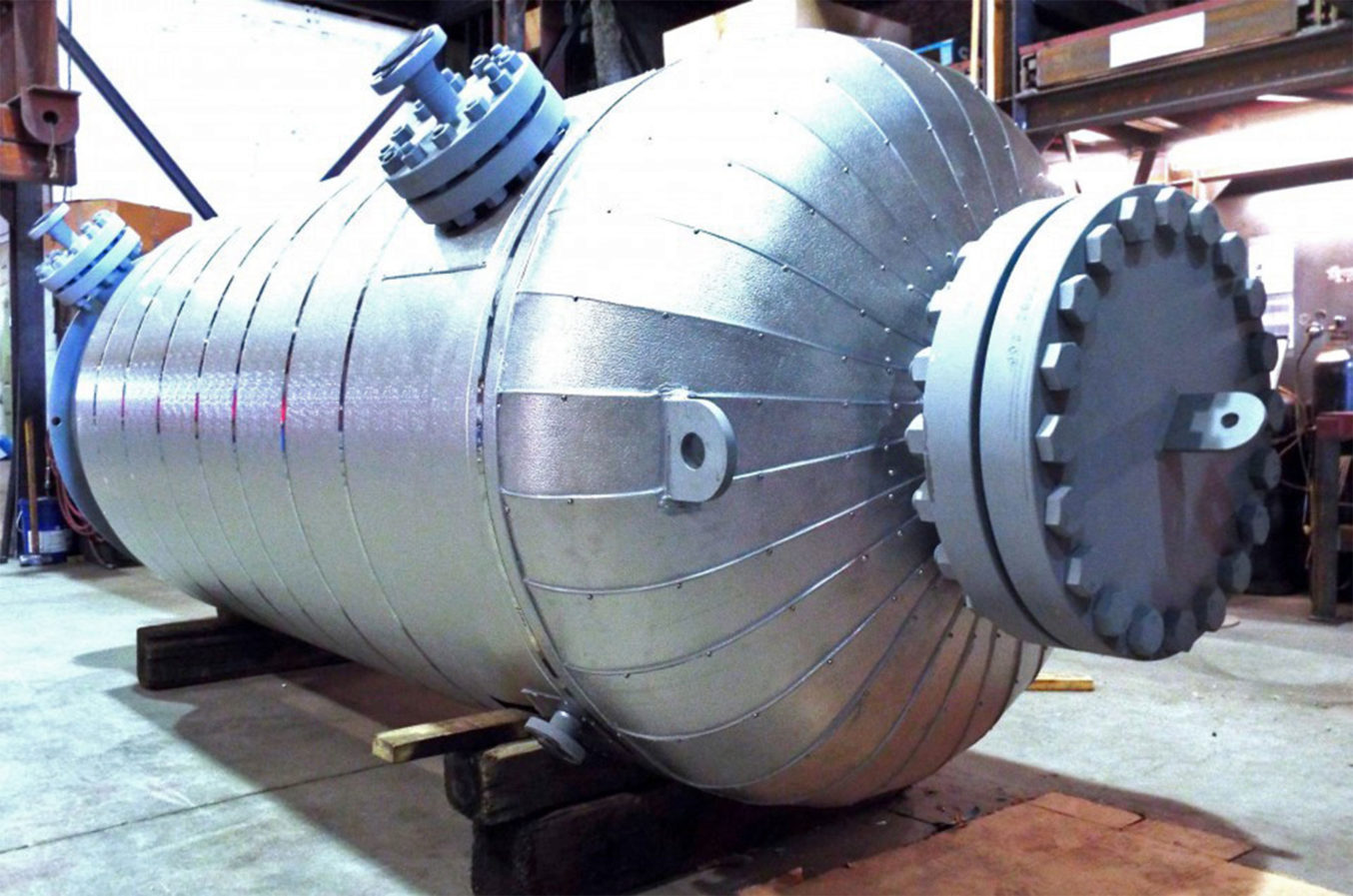

- Project Name: Chromoly Reactor

Our client utilizes a proprietary process to remove impurities from used lubricating oils. Once the impurities are removed, the recycled oils are ready to be resold for use in vehicles and industrial applications. One of their reactor vessels used in the process had worn out and they came to us looking for a replacement. They needed the replacement to last 30 years under extreme conditions. We provided a chromoly reactor, certified for service at 800°F at over 1,300 PSI. Completed, the vessel was 14′ long with a diameter of 4′ and weighed approximately 13,000 lbs. The nature of welding chromoly requires a high level of expertise and strict adherence to procedure.

Welding chromoly requires preheating to ~400°F. Failure to adequately preheat can increase to the likelihood of cracking.

The vessel required both preheating (prior to welding) and post weld heat treatment. Once we completed welding and non-destructive examination (NDE) of the 1½” thick vessel, we added insulation, stainless cladding and shipped it to our client. We look forward to building this vessel’s replacement in kind, circa 2044.